Application of Lansu laser marking machine in bearing industry

Application of Lansu laser marking machine in bearing industry

Bearing is an important component in contemporary machinery and equipment. Its main function is to support the mechanical rotating body, reduce the friction coefficient during its movement, and ensure its turning accuracy. China's bearing industry is developing rapidly, with a wide variety of bearing models. At the same time, the quality and technical level of products are constantly increasing. The industry is getting larger and larger, and the market is broad. There are more and more places where laser marking machines are needed.

Bearings usually need to be engraved with model information or brand logo after production, so as not to confuse the non-corresponding models, and it is easier to trace back. However, in the past, there were many problems when using the printing or coding process, such as:

1.The marking method will cause damage to the workpiece

2. The debugging of the marking effect requires longer man-hours

3. It takes a long time to change version

4. The coded logo is easily erased, fades quickly, and does not last long.

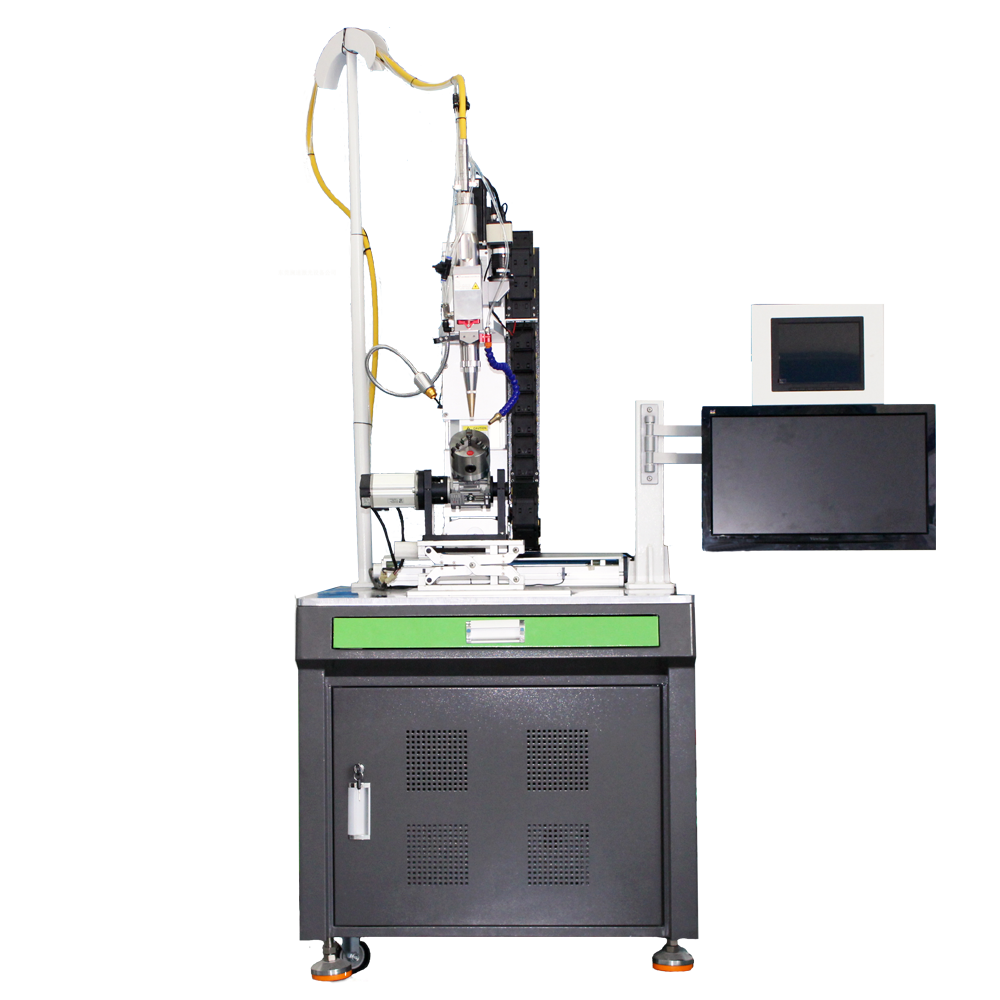

The marking software of the laser marking machine is powerful, compatible with files of Coreldraw, AutoCAD, Photoshop and other software; supports PLT, PCX, DXF, BMP, etc., and can directly use the SHX and TTF fonts; supports automatic encoding, printing serial numbers, batch numbers , Date, bar code, two-dimensional code, automatic number jump, etc., marking is convenient, and changing the marking content is also convenient and quick.

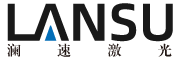

Lansu laser marking machine has high mechanical and electrical conversion efficiency. It adopts advanced laser and high-speed scanning galvanometer, high beam quality, environmental protection and energy saving, and the whole machine consumes less than 500W. Greatly save energy expenditure.